Thanks for stopping by. Enjoy my site.

Switch Stands

I wanted some operating switchstands for my garden layout, but didn’t want to spend a lot of money acquiring them.

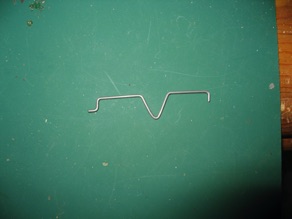

Since I need more than ten of these, I wanted to come up with an easy design that required minimal bending.

It was a great idea. They were very inexpensive, but just not suited to a ground level layout. I stepped on them a LOT.

I started these on May 1, 2005 and an article was published in Garden Railways magazine in June 2007.

I used 1/16” brass strips, 7/32” o.d. brass tube, .116” brass rod and some other parts to build a switchstand. My idea was to do very little bending.

A homebuilt jig holds the pieces in place to be soldered. I use a mini-torch to apply heat - and burn the jig.

A penny is soldered to the top, and the legs are soldered in place. Next, I drill a hole for the brass rod and cut slots in the penny.